About Esco Aster

Esco Aster leverages its expertise in life science manufacturing to provide end-to-end solutions for bioprocessing equipment and tools ranging from upstream to downstream applicationsEsco Aster is committed to make complex manufacturing simple via the continuous manufacturing platform, the Tide Motion technology. This cell culture technology provides a great tool for manufacturing human therapeutics such as vaccines and monoclonal antibodies and applications like cell-, gene therapy for regenerative medicine.Bioreactors

There are many different types of bioreactors and choosing the right bioreactor system for cell culture is crucial for success. The choice of bioreactor system to use greatly depends on the desired type of cells to be produced, the process of the cell culture, and the product density. Esco offers different types of bioreactors, suited for different types of cells, applications, and scales.

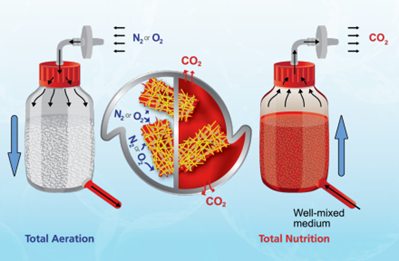

Tide Motion Bioreactors

The term ‘Tide Motion’ came about through the cyclical high rise and low rise of the bodies of water on earth. Similarly in a bioreactor, this is the gentle upward and downward movement of the culture medium to provide alternate aeration and nutrition exposure to cells. This favorable culture environment that limits shear stress produces over 1x106 cells/mL in just one 500 mL culture bottle. The Tide Motion bioreactors are available in single use or multiple use with automated systems for parameter control and harvesting procedures.

Tide Motion features:

- High Density 3D Adherent Culture with Macroporous Carriers

- In vivo like Culture with up to 2x108 cells per 500 mL of culture (cell density for stem cells)

- Scalable Platform in batch, fed-batch, and perfusion process modes

- Reduced Equipment Footprint

- Automated and Closed System for cGMP commercial production

- Perfectly suited for stem cell, vaccine, cosmeceutical, extracellular vesicle production

- Combination technology: Multiple-use or Single-use Components

- Linearly scalable from bench to manufacturing scale

- Dual oxygenation feature

- Run in normal or hypoxic conditions

- Various Process Modes:

- 100% Media Exchangeo Batch

- Fed-Batch

- Perfusion

These bioprocessing tools provide a reliable and linearly scalable outcome from small scale to production scale. Join the Tide for easy to use, cost-effective culture over static 2D culture systems.

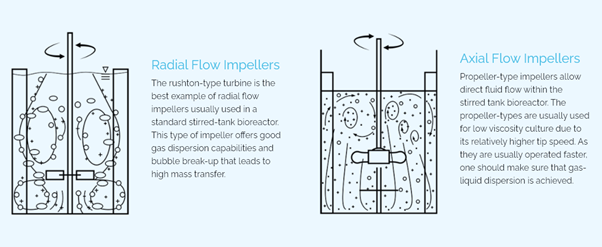

Stirred tank Bioreactors

This type of bioreactor is commonly used for fermentation or microbial culture applications. It adapts the same, conventional stirring method for culture and has different fluid dynamics for agitation. This agitation is done through impellers that have different designs to cater high oxygen transfer during cell culture.

Stirred Tank Features:

- Perfectly suited for microbial, yeast, fungi, enzyme, antibody production

- Reliable process performance with data tracking

- Compact and flexible design for a minimal footprint (bench-scale systems)

- Process scalability from research to manufacturing scale

- Configurable processes for meeting user’s requirements

- Different impeller designs available for optimum mixing conditions

- Supports batch, fed-batch, and perfusion process modes

CelCradle™ | Perfusion Operation | Esco VacciXcell

TideXcell® Harvesting System | Quick Features | Esco VacciXcell

CelCradle™ Benchtop Bioreactor | Quick Features | Esco VacciXcell

Bioprocess in Action: Esco VXL™ Hybrid | Esco VacciXcel

Rolling with the Tide: CelCradle™ Benchtop Bioreactor | Cell Harvesting | Esco VacciXcell

TideXcell® Harvesting System | Quick Features | Esco VacciXcell

TideXcell® Bioreactor | Quick Features

CelCradle™ Benchtop Bioreactor | Quick Features | Esco VacciXcell

StirCradle™ Bioreactor/Fermenter | Quick Features