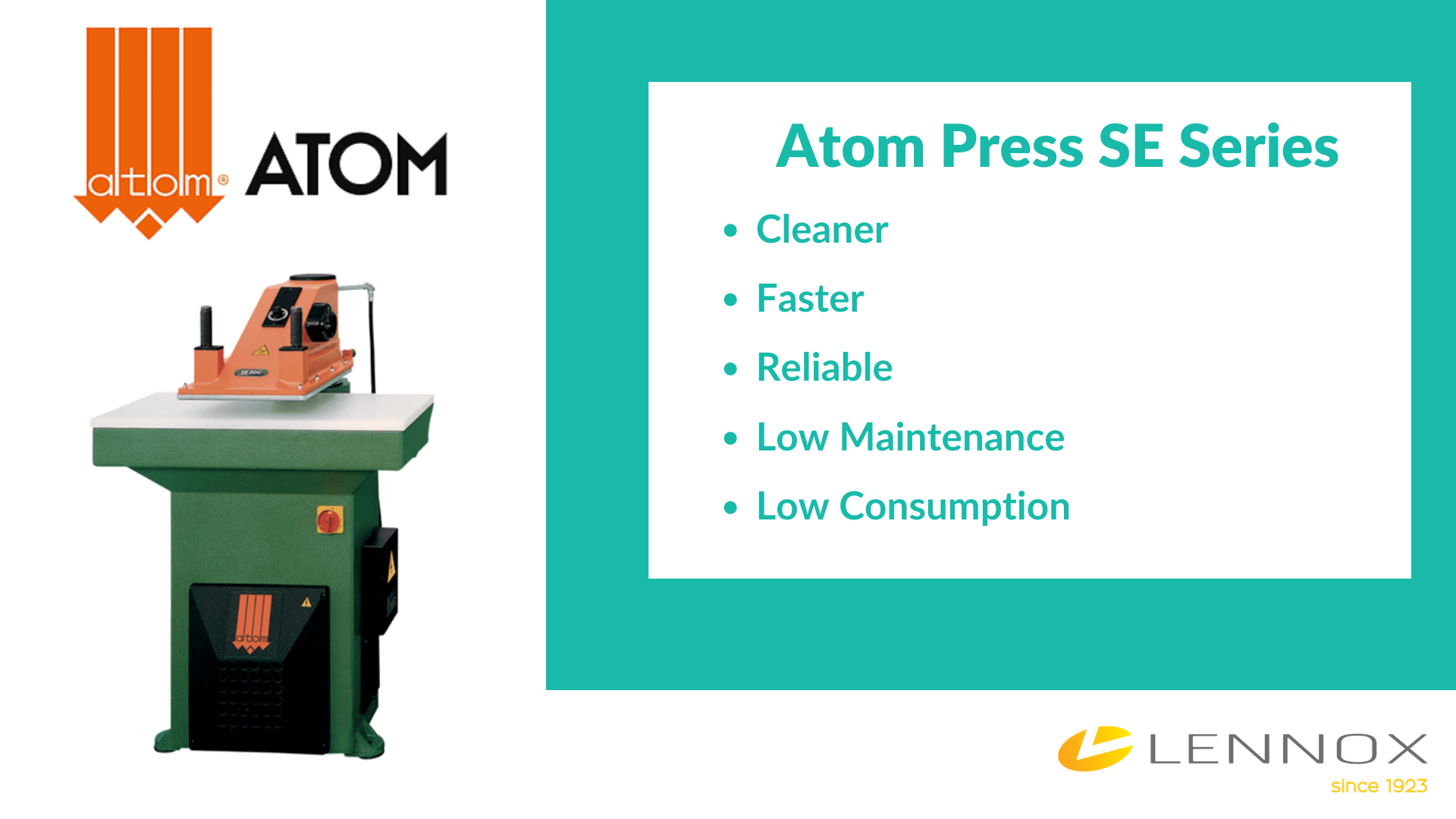

Product Spotlight: Atom Press SE Series

Product Spotlight: Atom Press SE Series

When it comes to taking on a challenge, Lennox strives to consistently improve on our customer services.

Recently we were commissioned to install an Atom Press SE series which was being used in a regulatory setting for the creation of mesh inserts for medical use. The SE creates a circular pre-cut mesh, which is then inserted into the body for hernia treatment.

The Atom Press SE series is a cleaner, faster, and more accurate version of the Atom Clicking Press. With 70-years' experience designing and manufacturing clicking presses, Atom provides products that are guaranteed in reliability, low consumption, maintenance-free, and a quick return on investment.

The exclusive hardware designed by Atom ensures steady cut pressure all day long, maximum speed, cutting accuracy and arm rotation. The SE is air operated as opposed to manual, designed to require minimal human effort, leading to more consistency between different users.

As our client was intending to use the press within a regulatory setting, it needed an installation qualification (IQ), as well as an operation qualification (OQ).

Atom does not provide an IQOQ, so this is where the Lennox team took it upon themselves to create, document, and execute one specifically for the client.

This custom IQOQ, delivered by Lennox, supplied an audit trail from purchase to installation, enabling its use in a regulatory setting. We installed the SE in a soundproof booth, adding an extra layer of safety and reduced noise levels for analysts, alongside an easy and efficient experience.

Prior to their purchase, our client had been using a manual press to complete this process.

To learn more about the Atom Press SE Series, get in contact with our Head of Business Development Padraig Callan, padraig.callan@lennox.ie